Maggi BORING SYSTEM 800 GT EASY PROGRAMMABLE CNC BORING MACHINE

Product Features

AVAILABLE DIRECT FROM MAGGI ITALY - the Ideal solution for small furniture manufacturers aiming to improve the quality of the manufacturing process on a small budget.

To produce kitchens and bespoke pieces of furniture.

High-accuracy, versatility and productivity.

- Intuitive, smartphone type interface

- Configurable equipment: choose your solution

- CNC programmable machining

- Small footprint: 3 sqm

- Easy maintenance and low power consumption

Ten-year experience, 100% made-in-Italy machines abiding by the highest quality standards as a result of the "Lean" manufacturing process, also known as "Toyota System".

IF YOU WOULD LIKE TO NO MORE ABOUT THIS PARTICULAR MACHINE PLEASE ENQUIRE TODAY AND WE WILL ADVISE MAGGI TO MAKE CONTACT WITH YOU.

_______________________________________________________________________

Maximum panel dimension X-Y-Z mm 3000 x 800 x 50 mm

Minimum panel dimension X-Y-Z mm 300 x 100 x 10 mm

Maximum panel weight 25 Kg

Max. axis speed (full and no load) 25 m/min - 40 m/min

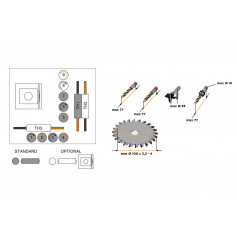

Double horizontal spindles (X axis) n.2 (TH1, TH2)

Double horizontal spindles (Y axis) n.1 (TH3)

Vertical spindles (Z axis) n.9 (4X-5Y)

Spindle interaxis 32 mm

Spindle speed 3200 RPM

Integrated blade unit, fixed position (X axis) n.1

Blade diameter 160 mm

Blade thickness 3,2 mm

Blade speed 5700 RPM

Motor power (spindles and blade) 2,2 kW

Electro spindle manual tool change (power - router holder type - collet chuck type - RPM) –––

Electro spindle manual tool change (power - collet chuck type - RPM) –––

Electro spindle manual tool change (power - collet chuck type - RPM) –––

Total power (full-optional) 3 kW ( 8 A)

Dust-collection nozzle diam. 100 mm

Air pressure 6 bar

Air consumption Q. = 750 m3/h

Overall dimensions - net weight 1830 x 2000 x 1800 mm. - 975 Kg

Package dimensions (pallet) - gross weight 2090 x 2060 x 1900 mm - 1.060 Kg

Technical specification

- 7 Vertical Spindles

- N.1 double horizontal -spindle TH1 (X axis) for back/ forth drilling

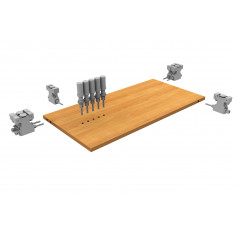

- Manual SIDE-ALIGNER

- PANEL EDGE-READER for perfect panel joints

- Teleservice Software

- Dust-collection nozzle

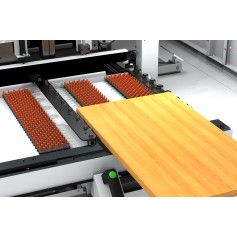

- Wokring table with GENTLE BRUSHES to avoid storage of dust and shavings.

- Working process can be in a cycle or back to the operator

- ______________________________

- HARDWARE & SOFTWARE

- 12" touch-screen - NO TEXT System, patented by Maggi

- USB and Ethernet ports for file uploading, on-line assistance and system upgrades

- System based on Linux Kernel

- Up to 1.000 working programs storable

For further information

Call us on 0116 2861617 or email [email protected]